Siam Industrial Machinery Co.,Ltd. [SIMC]

สรุปสินค้าและบริการหลักดังนี้The main products and services are summarized as follows:

บริษัทฯ มิได้แต่เป็นเพียงตัวแทนจำหน่ายสินค้า-บริการเท่านั้น แต่เรายังเป็นผู้นำในการช่วยลูกค้าลดภาระค่าใช้จ่ายเกินความจำเป็นโดยการแนะนำเครื่องจักรประหยัดพลังงานให้กับลูกค้า รวมทั้งลดแรงงานและลดความผิดพลาดจากการผิดพลาดของมนุษย์ (Human Error) ด้วยการเสนอระบบออโตเมชั่น (Automation)

The company is not only a distributor of products - services. But we are also the leader in helping our customers reduce their unnecessary expenses by introducing energy-saving machines to customer. Including reducing labor and reducing human error (Human Error) by offering automation systems

ROTATING EQUIPMENT (อุปกรณ์หมุน)

บริษัทฯ มีอุปกรณ์หมุนเพื่อตอบสนองความต้องการของลูกค้า ไม่ว่าจะเป็นอุปกรณ์หมุนในโรงงาน เช่น พัดลม โบลเวอร์ ปั๊ม ปั๊มเกียร์ คอมเพรสเซอร์ ฯลฯ เพราะเราเป็นบริษัทตัวแทนนำเข้าหลักจากต่างประเทศ

The company has rotating equipment to meet customers requiement, whether it is rotating equipment in factories such as fans, blowers, pumps, gear pumps, compressors, etc. The company is the main importing agent from abroad.

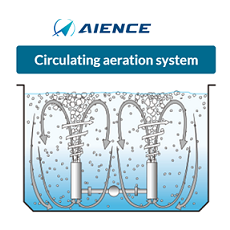

SOLUTION SYSTEMS (เสนอการแก้ปัญหา)

บริษัทฯ มีทีมเทคนิคที่เชียวชาญ ไม่ว่าจะช่วยแก้ปัญหาด้านมลภาวะ ควันดำทางอากาศ, ตะกอนจากบ่อบำบัดน้ำเสีย หรือ ออกแบบเครื่องดูดน้ำมัน หรือฝุ่นในไลน์ผลิต

The company has a professional technical team. whether to help solve the problem of pollution Black smoke from the air, sludge from wastewater treatment ponds or oil suction design or dust in the production line, etc.

SAVING ENERGY (สินค้าประหยัดพลังงาน)

บริษัทฯ วิเคราะห์และแนะแนวทางการประหยัดพลังงานที่เป็นรูปธรรม เช่น การเปลี่ยนเครื่องจักรในระบบบำบัดน้ำเสีย ระบบความร้อน ระบบการทำความเย็น

The company analyzes and recommends practical energy-saving guidelines for customers such as replacing machinery in wastewater treatment systems, heating systems, cooling systems, etc.

AUTOMATION (ระบบการทำงานอัติโนมัติ)

บริษัทฯ เป็นตัวแทนจำหน่ายและออกแบบระบบการทำงานของเครื่องจักรอัตโนมัติเพื่อช่วยลูกค้าแก้ปัญหาในไลน์ผลิตไม่ว่าจะเป็น IAI, Nachi Robot, Fanuc Robot, Epson Rotot, Musashi เป็นต้น

The company is a distributor and design of automation systems to help customers solve problems in the production line, whether it is IAI, Nachi Robot, Fanuc Robot, Epson Rotot, Musashi, etc.

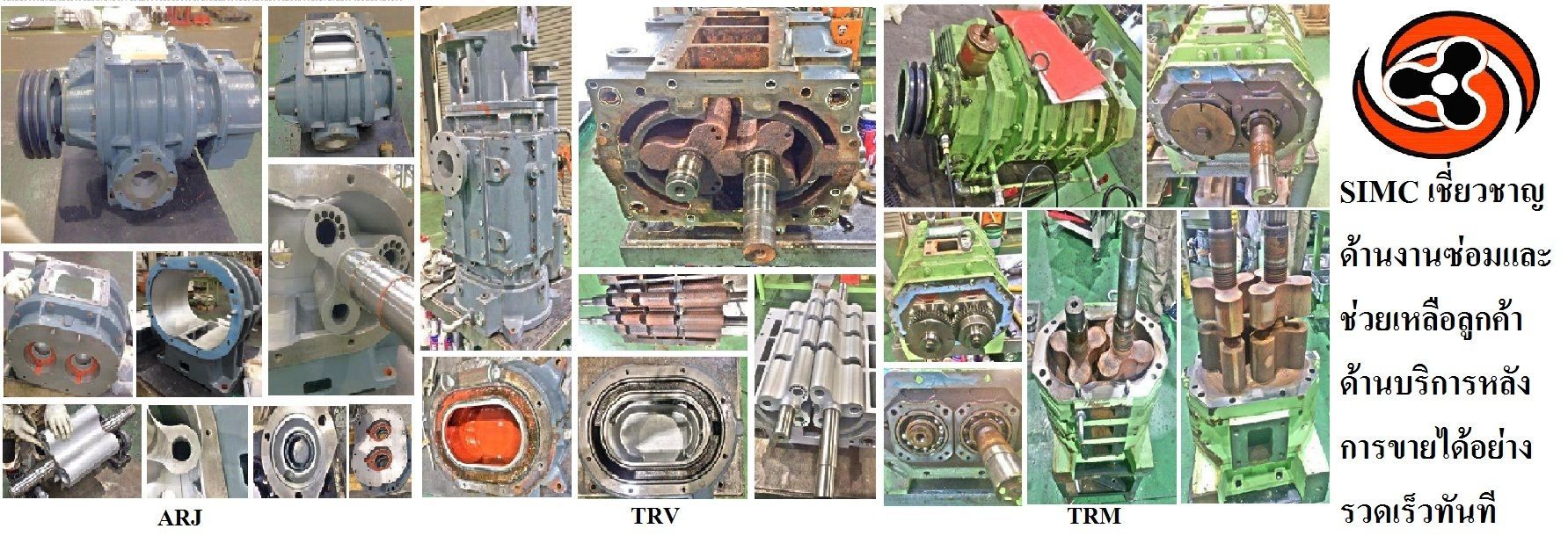

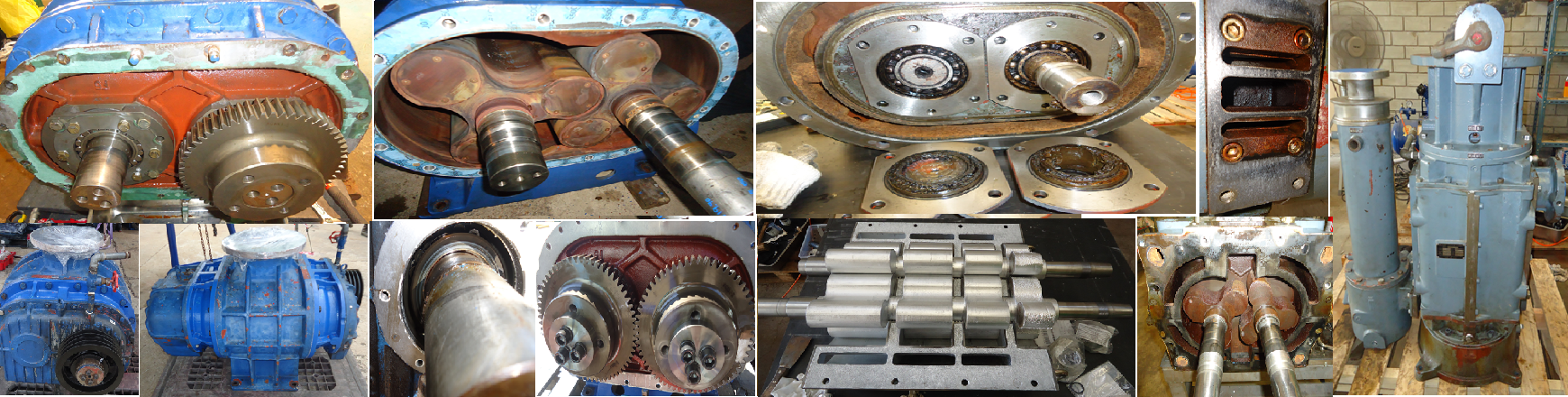

ยกเครื่อง แวคคั่มปั๊ม Overhaul Vacuum Pump

• รับงานสั่งทำตามแบบ เช่น JIX FIXTURE, PARTS FOR MASS PRODUCTION etc.

• รับงานสั่งทำสร้างห้องเก็บเสียงเครื่องจักรตามแบบ หรือออกแบบเฉพาะด้าน ใช้ใยหินซับเสียงอย่างดี

• รับงานติดตั่ง-รื้อถอน-ผลิต ทั่วไปเช่น : ก่อสร้างเครื่องชาร์จแบตเตอรี่, ติดตั่ง-รื้อถอนระบบท่อ, ก่อสร้างคลังเก็บสินค้า, ก่อสร้างเต๊น, สั่งทำระบบกำจัดฝุ่น

• จำหน่ายอะไหล่เครื่องจักรทุกชนิด

• จำหน่าย/สั่งทำอุปกรณ์เสริมเครื่องจักรเช่น ท่อเก็บเสียง, เกจวัดแรงดัน, มอเตอร์, สายพาน เป็นต้น

• จำหน่ายฟิลเตอร์อุตสาหกรรมทุกชนิด

• รับซ่อมอะไหล่รวมทั้งงานกลึงเช่น แมคคานิคอลซีล โดยวิศวกรเชี่ยวชาญเฉพาะด้าน

• บริการตรวจวัดและวิเคราะห์สมรรถนะ/ประสิทธิภาพของเครื่องจักร

• ซ่อมบำรุงอุปกรณ์ที่เกี่ยวข้องกับสินค้าที่จัดจำหน่ายทุกชนิดรวมทั้งงานเช็คซ่อมบำรุงเชิงป้องกัน (PM)

• Made to order such as jix fixture, parts for mass prod. etc.

• Made to order for Acoustic Enclosure drawing or design for customer.

• installation-demolition-fabriaction works such as: construction of battery chargers, installation-demolition of pipe systems, construction of warehouses, construction of tents, ordering a dust removal system.

• Distribution of spare parts for all kinds of machinery.

• Selling/ordering machine accessories such as Silencers, pressure gauges, motors, v-belts, etc.

• Sell all kinds of industrial filters.

• Repairing spare parts, including lathe work such as mechanical seal by specialized engineers

• Service for measuring and analyzing machine performance/efficiency.

• Maintenance of equipment related to all types of distributed products, including preventive maintenance checks (PM).

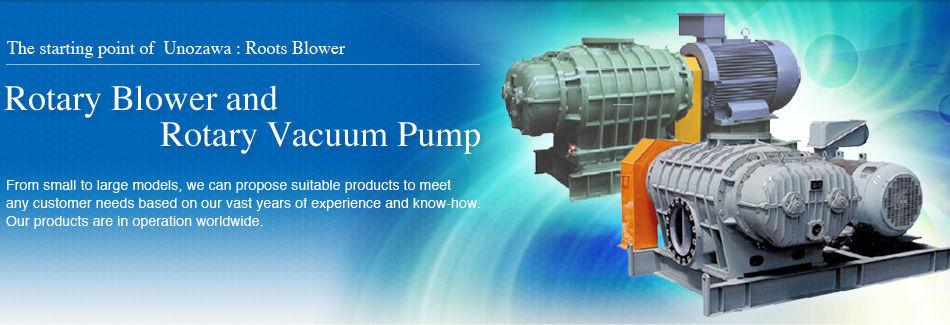

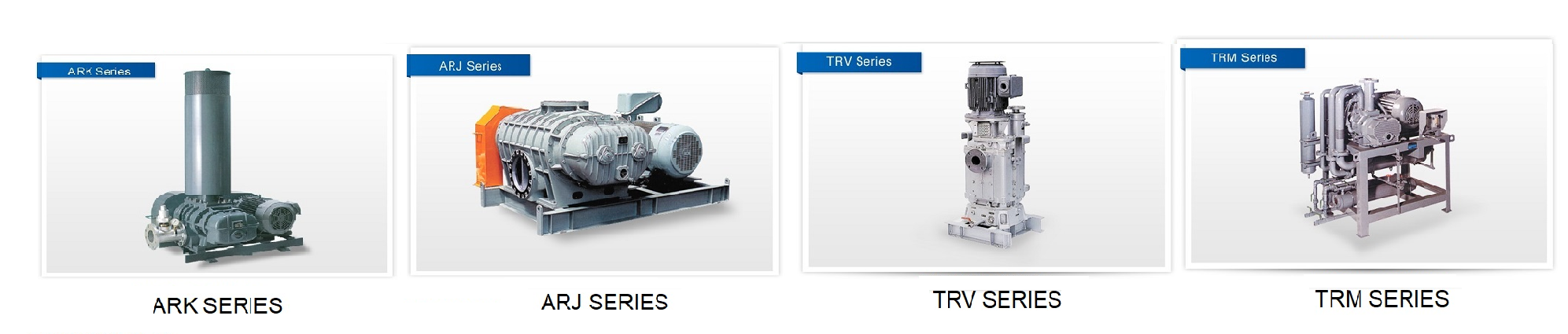

บริษัทฯ เป็นตัวแทนจำหน่ายโบวเวอร์/แวคคั่มปั๊มยี้ห้อ Unozawa (ยูโนซาว่า) ในไทยเป็นทางการบริษัทเดียวในประเทศไทย ดูแลงานขายเครื่องจักรใหม่ อะไหล่ และงานซ่อม

The company is sole agent for Unozawa Rotary Blower, Dry Vacuum Pump, Spare parts and overhaul service in Thailand.

โบวเวอร์/แวคคั่มปั๊มยี้ห้อ Unozawa (ยูโนซาว่า) สามารถประยุกต์ใช้งานได้ไม่ว่าจะเป็นงานแอร์และแก๊สพิเศษRotary Blower / Dry Vacuum Pump Unozawa can be use for AIR / GAS

ตัวอย่างการใช้งานโบวเวอร์/แวคคั่มปั๊มยี้ห้อ Unozawa (ยูโนซาว่า) เช่น การขนส่งลำเลียงวัสดุด้วยลม, การดูดสูญญากาศ, การเป่าอากาศเพื่อเพิ่มออกซิเจนในน้ำ, แวคคั่มในไลน์ผลิต, แวคคั่มฝุ่นเชื่อม เป็นต้น

Example Application Rotary Blower / Dry Vacuum Pump Unozawa : pneumatic conveyer, areation , Vacuum for production line process etc.

สำหรับ โบวเวอร์/แวคคั่มปั๊มยี้ห้อ Unozawa (ยูโนซาว่า) นั้นทาง

UNOZAWA-GUMI IRON WORKS,LTD. ยืนยันว่า มิได้ตั่งบริษัทย่อยดังเช่น

Unozawa Machinery (Thailand) Co., Ltd. หรือบริษัทอื่นๆ

ปัจจุบันได้แต่งตั่ง บริษัท สยามอินดัสเทรียล แมชชีนเนอรี่ จำกัด เป็นตัวแทนจำหน่ายเครื่องจักร อะไหล่นำเข้า และการซ่อมบำรุง

แต่เพียงบริษัทเดียวในประเทศไทย

For the bower/vacuum pump brand Unozawa,

UNOZAWA-GUMI IRON WORKS,LTD. confirms that it does not establish a subsidiary such as

Unozawa Machinery (Thailand) Co., Ltd. or other companies.

At present, Siam Industrial Machinery Co., Ltd. has been appointed to be the only dealer in the sale of machinery, spare parts and maintenance in Thailand.

พลังงานสะอาดคือ ?

พลังงานที่ไม่ก่อให้เกิดผลกระทบต่อสิ่งแวดล้อมในทุกขั้นตอนของการใช้ ตั้งแต่การผลิตแปรรูป และการนำไปใช้งาน ซึ่งพลังงานสะอาดที่พบได้ในปัจจุบันคือ พลังงานแสงอาทิตย์ พลังงานน้ำ พลังงานลม พลังงานความร้อนใต้พิภพ และ พลังงานไฟฟ้า

ดังนั้น จะเห็นว่าหากเราใช้พลังงานสะอาดในโรงงานให้ได้มากที่สุดก็จะลด ค่าใช้จ่ายในการใช้พลังงาน และ อีกทั้งยังลดการใช้พลังงานของโลกอีกด้วย

บริษัทฯเราจึงมีความตั่งใจช่วยเหลือลูกค้าด้านการประหยัดพลังงานสะอาดโดยนำเครื่องจักรที่มีประสิทธิภาพที่มีนวัตกรรมใหม่ มาแทนที่นวัตกรรมเดิมเช่น

1. เปลี่ยนจาก Roots Blower เป็น => Atlas Copco Screw Blower (สกรูโบวเวอร์)

2. เปลี่ยนจาก Electric Heater เป็น => Heat Pump (ปั๊มความร้อน)

3. เปลี่ยนจาก Electric Chiller เป็น => Absorption Chiller

หรือนำเครื่องจักรอัตโนมัติ (Automation) มาแทนที่การทำงานด้วยคนเพื่อลดความผิดพลาด และเพิ่มผลผลิต

ข้อมูลข้างต้น หากลูกค้า ยังไม่แน่ใจว่าเครื่องจักรอะไรที่ประหยัดพลังงานได้อีกบ้างทางเรายินดีที่จะแนะนำแนวทางการประหยัดพลังงานโดยใช้หลักการไคเซ็น (Kaizen) คือ การเปลี่ยนแปลงให้ดีขึ้นโดยไม่มีค่าใช้จ่ายด้านการปรึกษาใดๆ

What is clean energy?

Energy that does not cause any environmental impact at every stage of use from production to processing and its use The clean energy that can be found today is Solar power, hydro power, wind power, geothermal power and electric power.

Therefore, if we use clean energy in the factory as much as possible, it will reduce The cost of energy consumption and also reduce the energy consumption of the world as well.

Therefore, our company is willing to help customers in saving energy and clean by introducing efficient machines with new innovations to replace the original innovations such as

1. Changed from Roots Blower to => Atlas Copco Screw Blower (Screw Bower).

2. Change from Electric Heater to => Heat Pump (Heat Pump).

3. Changed from Electric Chiller to => Absorption Chiller.

or use automatic to replace human work to reduce mistakes and increase productivity